STRENGTH OF YAMATOYAMATOの強み

03大型部品 難削材対応

各加工工程で大型部品に対応

和コーポレーションでは、大型部品に対応した各種設備を整えています。

各工程での対応サイズは以下の通りです。

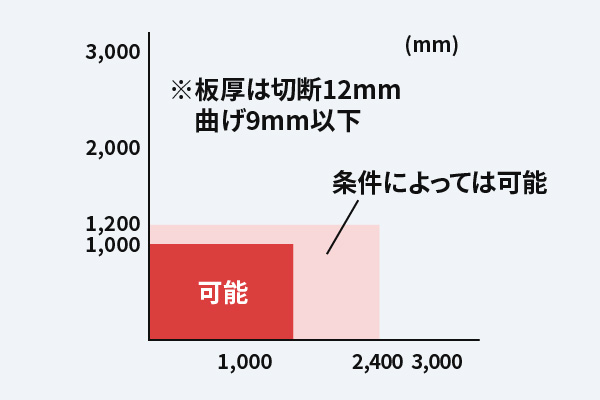

■金属部品 加工可能サイズの目安

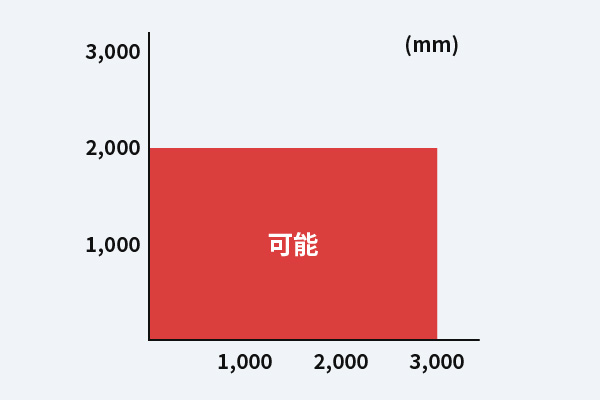

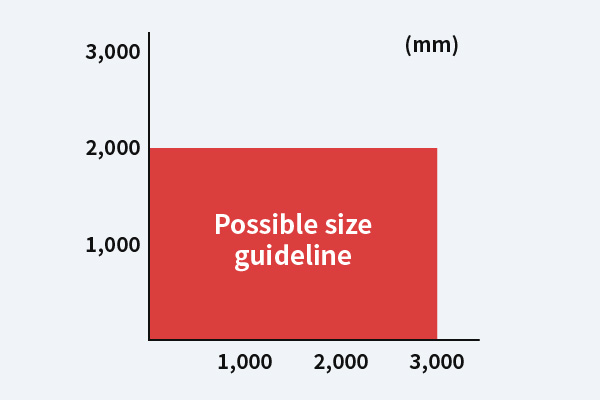

切削 フライス加工

可能サイズ目安

加工対象素材ステンレス、アルミ、銅、鉄、インコネル合金、チタン合金、ハステロイ合金、モリブデン 等

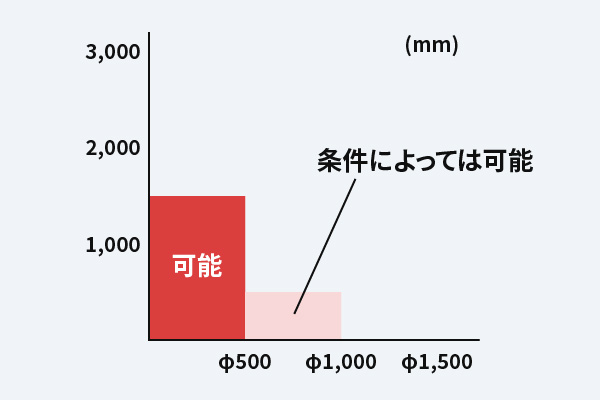

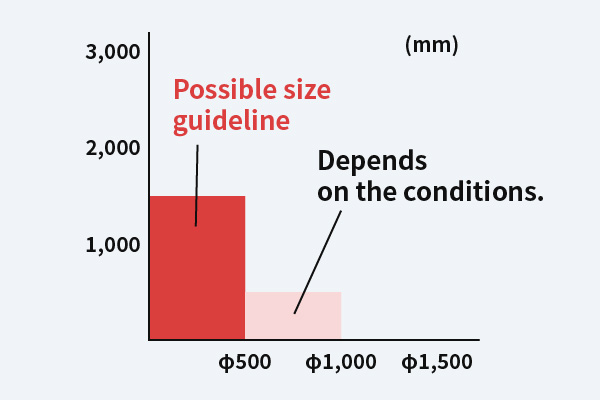

切削 旋盤加工

可能サイズ目安

加工対象素材ステンレス、アルミ、銅、鉄、インコネル合金、チタン合金、ハステロイ合金、モリブデン 等

精密板金加工

可能サイズ目安

加工対象素材ステンレス、アルミ、鉄、真鍮

チタンやモリブデンなどの難削材の加工実績

和コーポレーションは5軸加工機・複合旋盤を多数所有し、複雑な形状加工を得意としています。ステンレスやアルミ・鉄といった一般的な材質の金属はもちろん、チタンやモリブデンなど、難削材の加工に関しても多数実績を持っています。また、電子ビーム溶接加工機を保有しているので、チタンの溶接も可能です。

対応素材一覧

| 材料名 | 材料記号 | ワークサイズ(例) | 精度 | 加工形状 |

|---|---|---|---|---|

| アルミ合金 | A5052 | 径方向 ±0.008 | 丸物、角物、チャンバー | |

| A1050 | 長手方向 ±0.05 | |||

| A1070 | φ25x125.75L | 同軸度 φ0.01 | ||

| A2017 | 300x780x830 | |||

| A5056 | 径方向 ±0.008 | |||

| A5083、A6061、A6063、A7075 | ||||

| ステンレス鋼 | SUS303 | φ86x58L | 径方向 ±0.008 | 丸物、角物、板 |

| SUS304 | 55x280x1792 | 長手方向 ±0.05 | ||

| SUS304L | 平面度 ±0.3 | |||

| SUS316 | 14x20x41 | 平行度 φ0.03 | ||

| SUS316L | ||||

| SUS347、SUS440C、SUS403、 SUS410、SUS430、SUS440C、 SUS630、SUS329J3L、 SUS329J4L、SUS420J2 |

||||

| 鋼 | S25C | 300x780x830 | 丸物、角物、板 | |

| S35C、S45C、S50C、SS400 SM400A、DC11、SCM435、SKD11、SKD61、SUY、SK105、SUJ2、SUH3 |

||||

| 純銅 | C1020 | Φ133×205.6L、 11.9x55x80 |

径方向 ±0.025 長手方向 ±0.05 同軸度 φ0.05 |

丸物、角物 |

| C1100、C2801、C3604、C6191 | ||||

| チタン | 純チタン | φ68x144.5L | 径方向 ±0.05 長手方向 ±0.05 真円度 ±0.1 |

丸物、角物 |

| 64チタン | ||||

| SUSTi | Φ348x41L | |||

| 合金 | TZM(Ti-Zr-Mo)合金 TZM-Alloy(Titnaium-Zirconium-Molybdenum Alloy) |

φ48.3×283L | 径方向 ±0.003 長手方向 ±0.004 同軸度 φ0.02 |

|

| インコネル 600、アロイ20、モネル、ハステロイ、ステライト、STAVAX | ||||

| 樹脂 | ポリアミド |

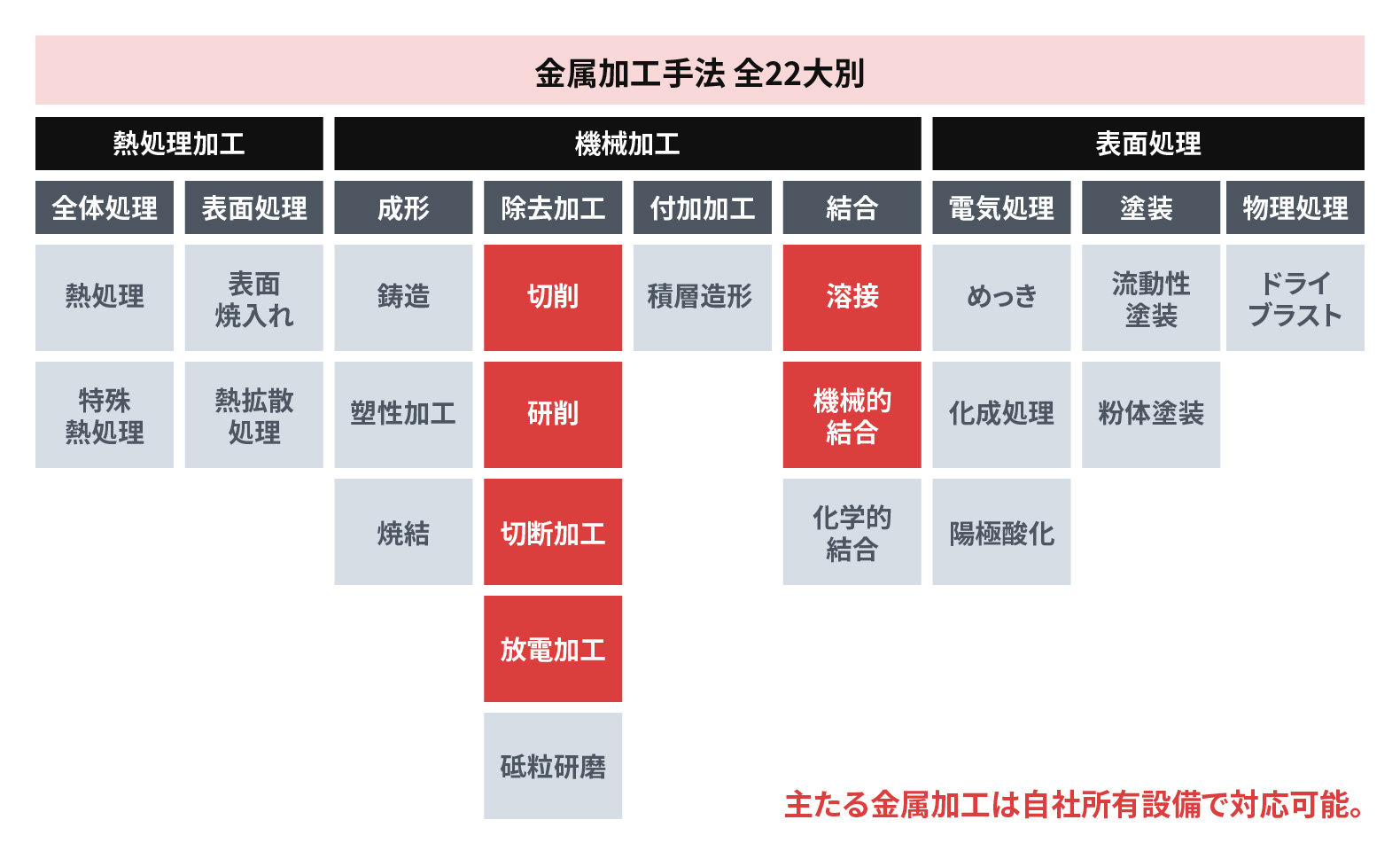

和コーポレーションで対応可能な金属加工

金属加工の工程は主に22に大別されますが、和コーポレーションでは7種類の工程に対応しています。

金属の機械加工の主たるメニュー(切削・研削・切断加工・放電加工・積層造形・溶接)は自社所有設備で担える上、電気処理(めっき)や塗装の表面処理も長岡近郊のネットワークにて御要望にお応え出来ます。

難削材や特殊な加工を実現する保有設備

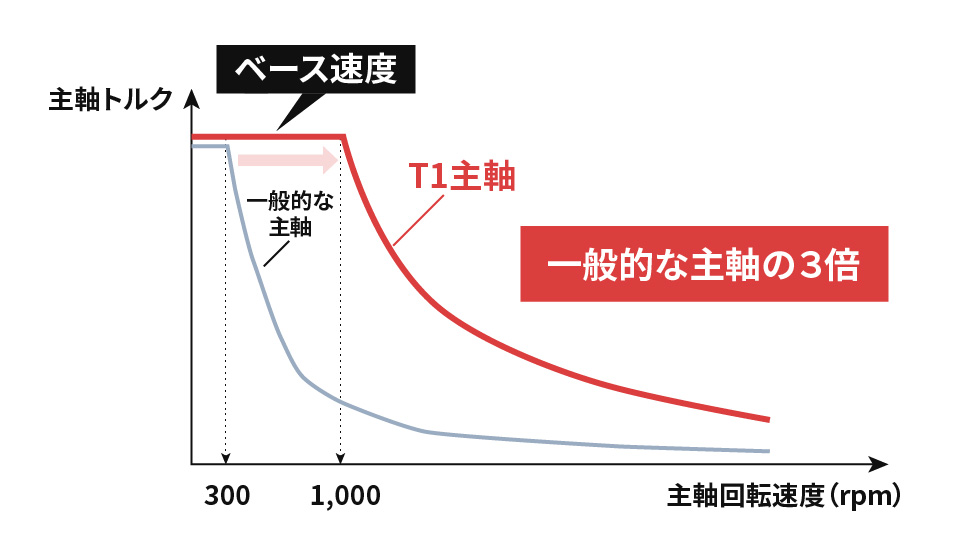

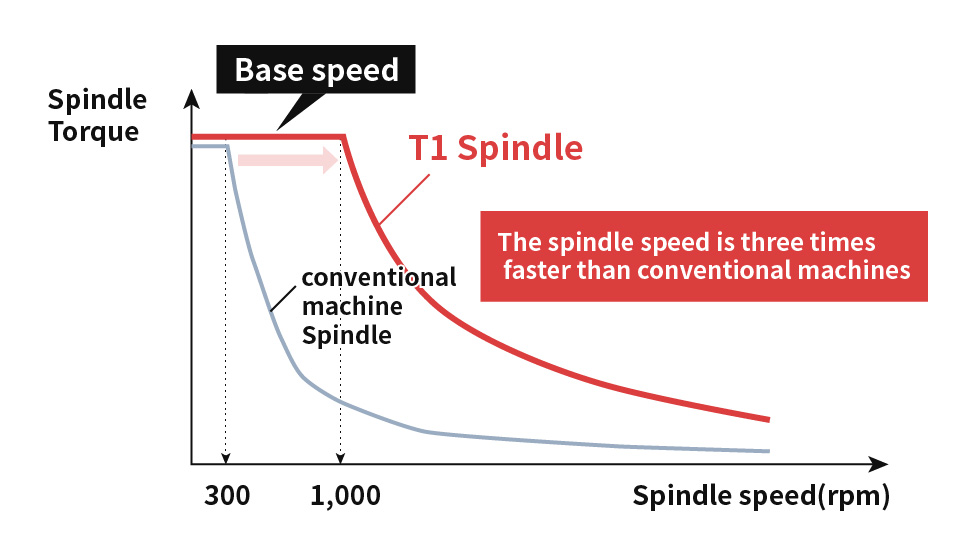

■5軸制御マシニングセンタ T1 (マキノ社製)

T1 5軸制御横形マシニングセンタ

大型の難削材(ステンレス・チタン)も加工可能なマシニングセンタ本T1装置はチタン合金、インコネル、ステンレス等の航空機部品の難削材加工に特化したマシニングセンタ。主軸の低速領域での高トルクが高速域まで継続しているのが特長。難削材の他にアルミ合金も高精度加工が可能です。

| 対象ワーク: | 最大1,000×1,000mm |

|---|

詳しくはこちら(メーカーサイトへ)

詳しくはこちら(メーカーサイトへ)

詳しくはこちら(メーカーサイトへ)

詳しくはこちら(メーカーサイトへ)

■電子ビーム精密溶接加工機(三菱電機社製)

EBM-6LB-1VR-C5050

需要急進中の耐熱金属材料の溶接も可能な電子ビーム加工電子ビーム加工とは、加熱した電子の束(ビーム)を被加工物に照射し、加熱・溶融させる加工法。(テレビのブラウン管と同じ構造)低ひずみで厚肉溶接が可能。銅やアルミなどの高反射材、チタンやタングステン、モリブデンなどの高融点材も加工対象。

| 対象ワーク: | 最大ワーク径 Φ450mm 最大高さ 450mm |

|---|---|

| 溶接径: | Φ350mm |

■ファイバーレーザーパンチ複合加工機 (TRUMPF社製)

TruMatic 6000fiber

ファイバーレーザー&パンチ複合加工機による高品質精密板金レーザー出力3kWにて板厚6mmまで加工可能

| パンチ最大加圧力: | 180Kn(18t) |

|---|---|

| 加工対象素材: | SUS,アルミ,真鍮 |

| 繰り返し加工精度: | ±0.03mm |

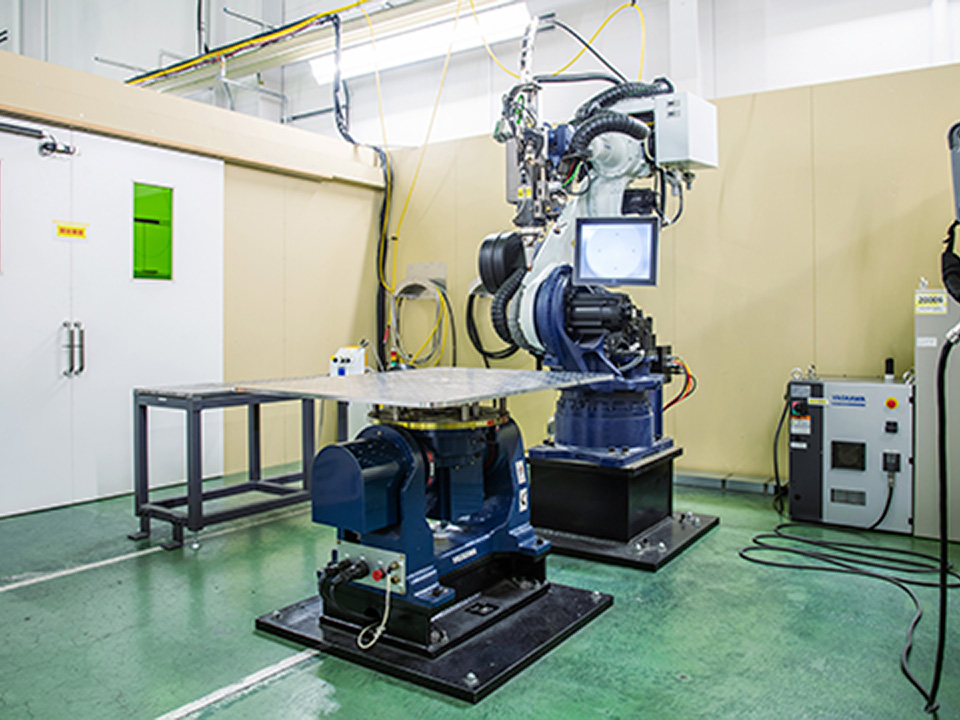

■YAGレーザー溶接ロボット (TRUMPF社製)

TruLaser Weld 5000

T1 5軸制御横形マシニングセンタは株式会社牧野フライス製作所の商標です。

EBM-6LB-1VR-C5050は三菱電機株式会社の商標です。

TruMatic 6000fiberはトルンプ 株式会社並びにTRUMPF SE + Co. KGの商標です。

TruLaser Weld 5000はトルンプ 株式会社並びにTRUMPF SE + Co. KGの商標です。

ファイバーレーザー×ロボット溶接による”盛りナシ”高品質溶接アーク溶接とは異なるレーザー溶接は1点に集中照射される為、熱が広がらず歪みや焼け焦げ少なく見た目はかなり美しく仕上げられます。電気パルスで発生させたYAGレーザーで母材を溶かして、溶接を行うので”盛り”も不要です。溶接はロボットによるプログラム制御にて、2軸ポジション台と連動して正確で誤差が極めて少ない安定した品質が実現致します。

主要用途は半導体設備関連、食品機械関連のカバー筐体等に採用いただいております。

ほかのYAMATOの強みを見る