STRENGTH OF YAMATOYAMATOの強み

06充実した設備と工場面積

- EQUIPMENT設備

- FACTORY工場

充実した設備で品質を保つ

和コーポレーションは5軸加工機・複合旋盤を多数所有しています。そのため、必要な加工設備のチョイスが的確に行えるため、加工の精度や安定性を高めることができます。また、1回セットするだけであらゆる角度から削れる設備が揃っているため、加工精度が作業者の技量によって変わることが少なく、安定した品質を保つことができます。

設備一覧

-

マシニングセンタ 材料の不要な部分を削り落とし目的のカタチに仕上げるため、 工作物の取り付け替えなしに、CNC制御による多種類の加工を行う工作機械。ATC(自動工具交換装置)を装備し自動で工具を使い分けます。弊社では軸数も3軸、5軸や、タイプも横型、縦型(立型)、門型とサイズや精度、形状に応じて多種多様な装置を所持しています。APC(自動パレット交換機)を装備機器も多数所持。量産にも対応しています。

-

複合加工機 NC旋盤にフライスの機能を搭載し、様々な加工ができるNC旋盤が複合加工機と呼ばれます。旋盤の段取り替えやマシニングセンタでのいくつかの工程を1台でこなすことが可能。取り換え作業を抑え、高精度な加工を実現します。弊社は数多くの複合加工機を所持しており短納期、高精度で市場の要求に応えています。

-

旋盤・その他 複合加工機だけでなく、NC旋盤も多数所持。また、大物や重量物の加工用として立形旋盤も所持しています。台数は少ないですが平面研磨機も所持しています。

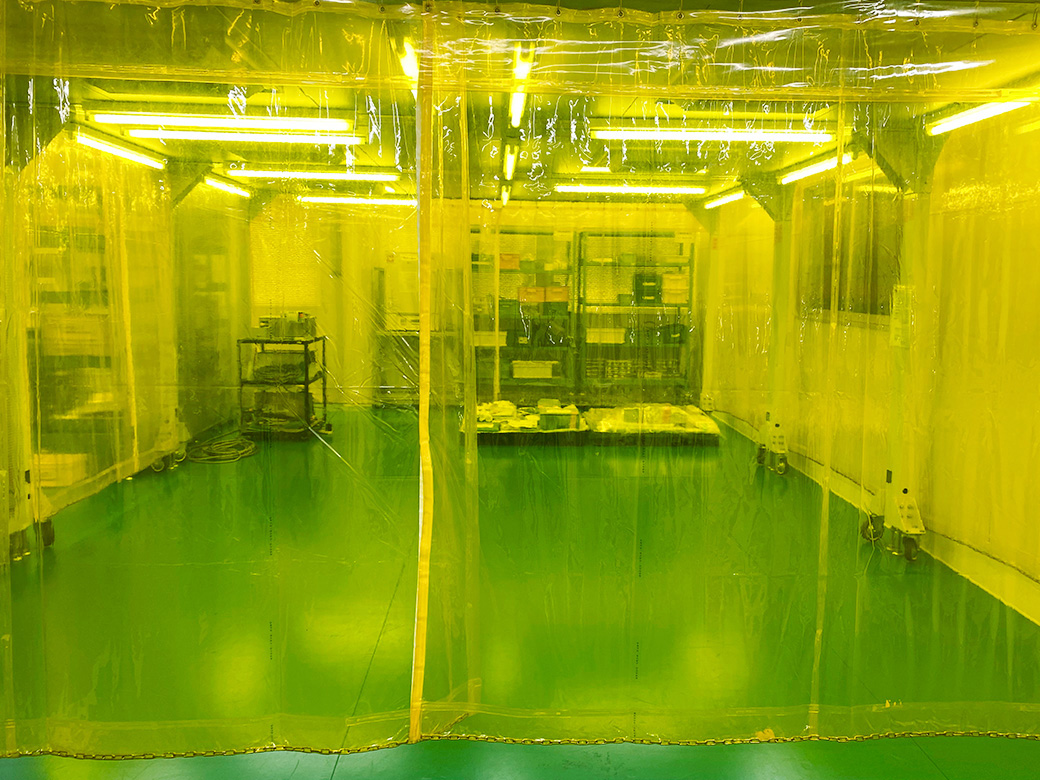

装置組立工場にはクリーンブースもあり、2.8tのガントリークレーンによる装置の移動や荷下ろしを簡便化するために構内へのトラックの乗り入れも可能な工場設計となっています。 -

Laser & Welding (精密板金) ATC搭載のファイバーレーザーによる薄板の切り抜き加工機や、サーボプレスによる板金から、スポット溶接機による溶接。装置用のフレーム溶接工程まで対応。薄板アルミからステンレス、鉄、チタンなど多種な溶接に対応しています。

-

品質管理設備 製造するパーツも大物であれば、検査室も大型です。3次元測定器を4台所持。サイズや精度によって使い分けをしています。画像処理を使った3次元スキャナーも所持しており曲面への測定に威力を発揮、高精度な部品の出荷に対応しています。

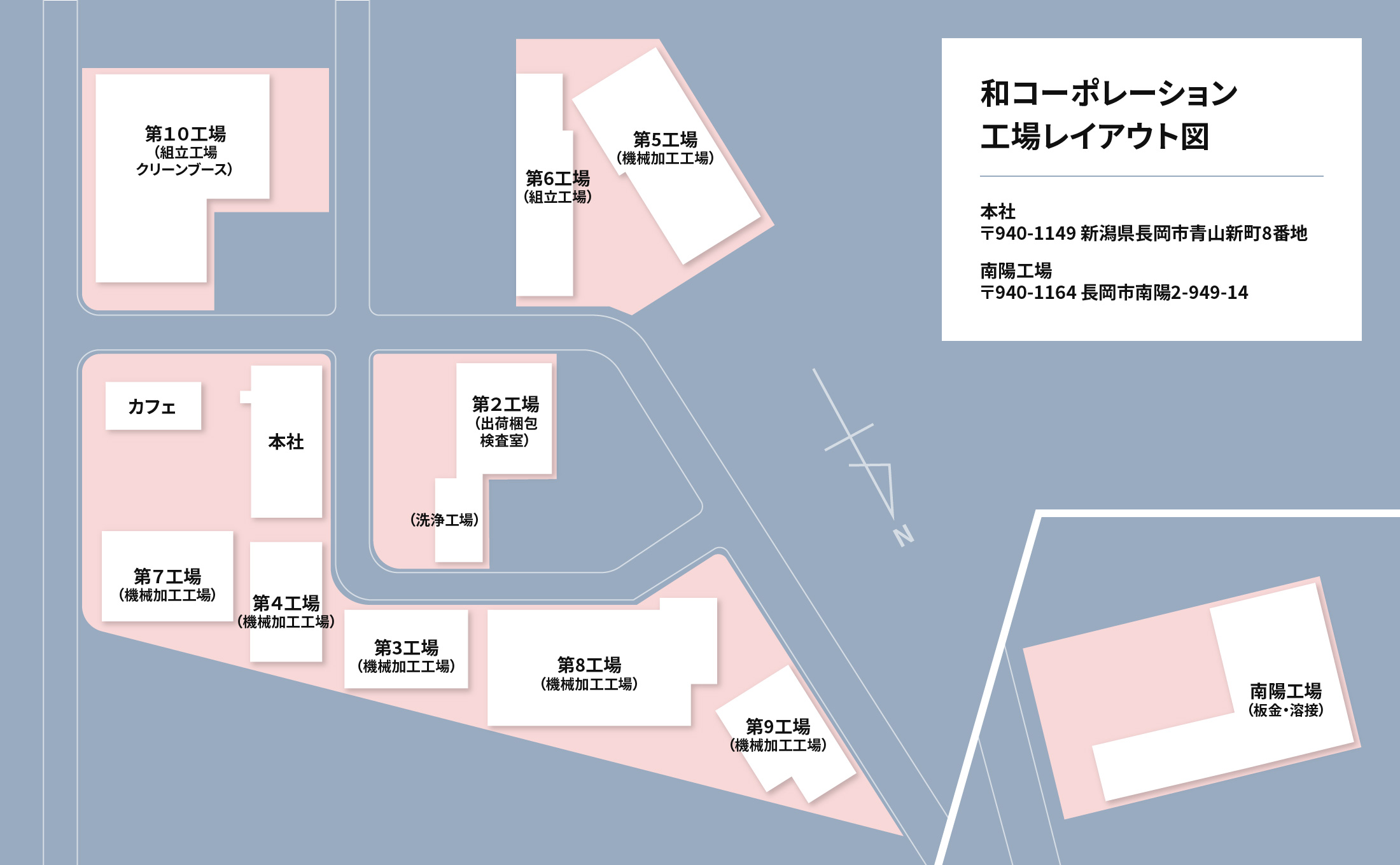

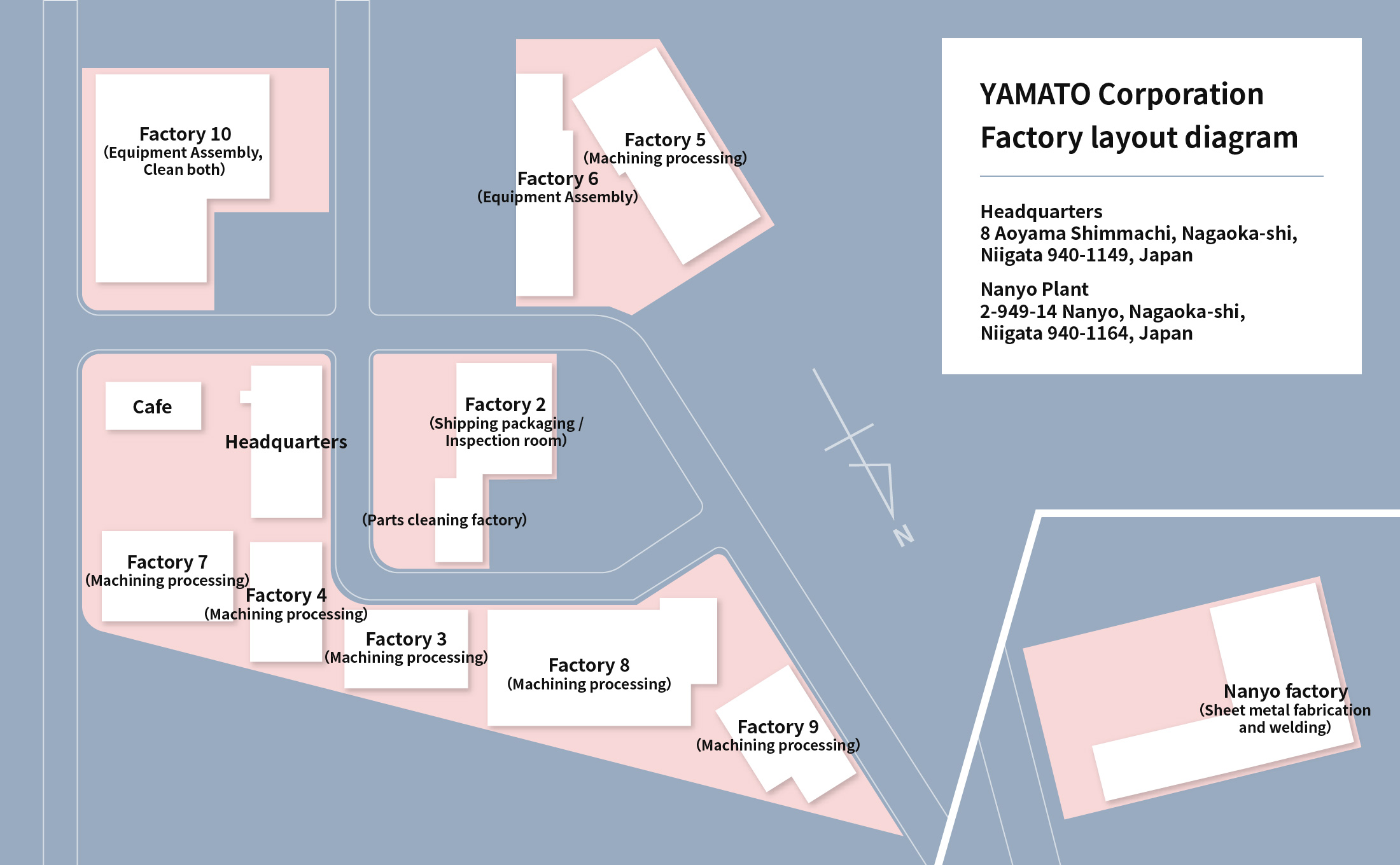

広い敷地に複数の工場を展開

和コーポレーションの本社では切削、組み立て、検査などの工場を集約。広い敷地を活かして、大型の設備や多数の設備を設置しています。また本社から少し離れた場所には、板金や溶接を行う南陽工場を設けています。

工場面積(建築面積)

| 本社工場/カフェ/第4工場 (機械加工工場) | 1001.75m² |

|---|---|

| 第2工場(出荷梱包 検査室)(洗浄工場) | 567.13m² |

| 第3工場(機械加工工場) | 408m² |

| 第5工場(機械加工工場) /第6工場 (組立工場) | 1296.17m² |

| 第7工場(機械加工工場) | 473.07m² |

| 第8工場(機械加工工場) | 1386.72m² |

| 第9工場(機械加工工場) | 423.1m² |

| 第10工場(組立工場 クリーンブース) | 1308.73m² |

| 南陽工場 (板金・溶接) | 2000m² |

| 総建築面積 | 8864.67m² |

クリーンブースも完備

非感光型のクリーンブースが横幅4500×奥行5500×高さ2150を2室。

横幅5000×奥行8000×高さ2900を1室設置。

クラス1000 @0.5umを維持。

コンタミに敏感な機器類の組み立てや調整を行っています。

横幅4500 奥行5500 高さ2150 (室内寸)

横幅4500 奥行5500 高さ2150 (室内寸)

横幅5000 奥行8000 高さ2900

横幅5000 奥行8000 高さ2900

ほかのYAMATOの強みを見る